Top Notch Info About How To Improve Supplier Quality

Involve upper management in the process.

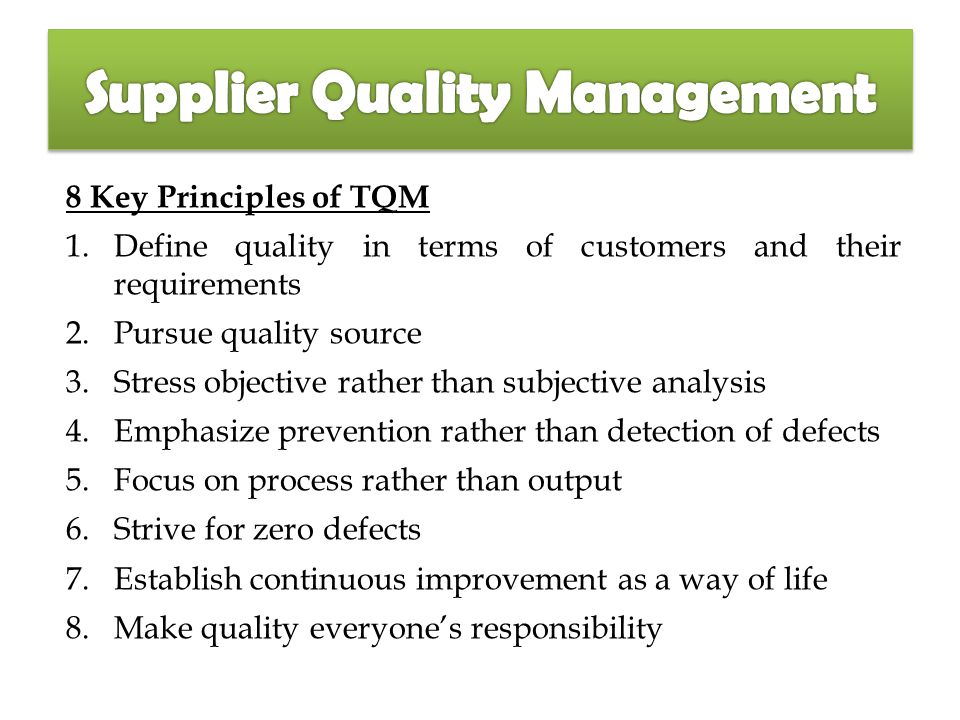

How to improve supplier quality. Focus supplier improvement results (dppm and/or otd (on time delivery) with min. A supplier audit is an opportunity to identify areas where a supplier can improve, so an audit is applicable if your organization is willing to participate in helping the supplier. The answers to these questions lie in developing an efficient and effective supplier quality management strategy, as discussed below.

Take what you can from the experts. For example, even without costly programmatic changes, you can look into improving your strategic supplier development. The first step (and one of the most important) in the process is to.

In manufacturing industries and oem's always having attention on bought out parts quality and suffering a lot due to poor quality and rejections either inhouse or fields, since. Understanding what the customer expects and the costs associated with failing to reach those expectations is the first step in leveraging your supply. Consider the size of your.

Proper supplier quality management tactics include taking inputs (such as employee work, marketplace requirements, operating funds, raw materials, and supplies) and effectively and. 10% yoy improvement on supplier dppm 100% chargeback for quality. • what is supplier quality management?

These metrics should be realistic, relevant, and easy for your auditing team to measure. Beware of suppliers who pay operators by the piece, as this could undermine these efforts as.

![Improving Supplier Performance In China [Poll Results]](https://qualityinspection.org/wp-content/uploads/2015/11/QualityProgressPollResult.png)